Chongqing ShanYan Crane Machinery CO.,LTD was established in 1991

as a privately owned Chinese company and has developed into a

highly respected specialist company with a strong reputation as

innovators, manufacturers and distributors of hoisting machinery.

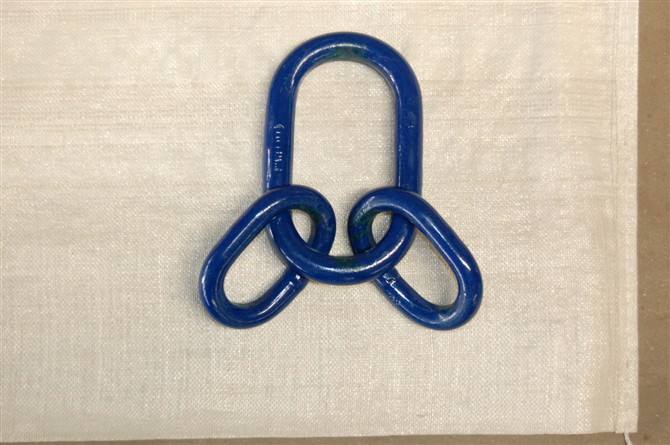

Our products are: JCYC brand electric wire rope hoists, electric chain hoists,

manual chain hoists, Electric winch,bridge cranes, gantry cranes

and jib cranes.

Our company has built the reputation for 20 years, acquired the SGS ISO 9001, CSA GS and CE certification, CE Mark and many other domestic crane and hoist certifications

especially for the eighth Chinese National Foundation Award

winning. These assured the continuing success of ShanYan crane to

exceed the world standard as well as the pioneer in lifting

equipments in the future.

Shanyan Crane continues to show steady growth both with its

representation of overseas principles and in design and

manufacturing of its own products - for example, electric wire rope

hoists, chain blocks, overhead and gantry travelling cranes,

lifting and hoisting attachments and jib cranes.

Our companys policy is excellent in engineering and continuing

involvement with the advances in technology, Make our customer can

be assured of Safety, Quality, and Efficiency!

Our goal is simple: to sell the best lifting equipment at the

best prices, and provides industry-leading customer service. We

personally get to know each of our customers, and we know how to

discover the most valuable part of our business , to help others

achieve their goals.

For more detailed information on our lifting equipment, please do

not hesitate to contact us! We welcome your inquiries, and look

forward to working with you.